Lactic acid-producing bacteria (LAB) are essential constituents of foodstuffs such as juice, vegetables and cereals. They are traditionally used for the production of fermented foodstuffs and probably contribute to fouling and spoilage. The occurrence of LABs is often not detected for several days, but then their number increases dramatically. QUALI-JUICE is an EU-funded collective research project which is able to detect quality deterioration by using a biosensor system. Countermeasures can be immediately initiated und thus economic loss prevented. The 17 international partners from science and industry recently presented the preliminary results from the project, which was launched in 2005, in Padua/Italy.

Bremerhaven, May 2008. Many factors influence the price consumers have to pay for juice. In addition to raw materials, the efficiency of the production process and output are also critical. The objectives of QUALI-JUICE are to reduce production costs by 3 percent and to improve the productivity of the fruit juice industry by around 80 percent by decreasing lost output. The project is running under the EU’s Sixth Framework Research Programme and has a total budget of 1.6 billion Euro, of which 1 billion Euro is funded by the European Commission. The achievements realised in 30 months of project work were presented during the last meeting. Results from tests with three offline sensors under real conditions were compared, in order to find the best available component for the process.

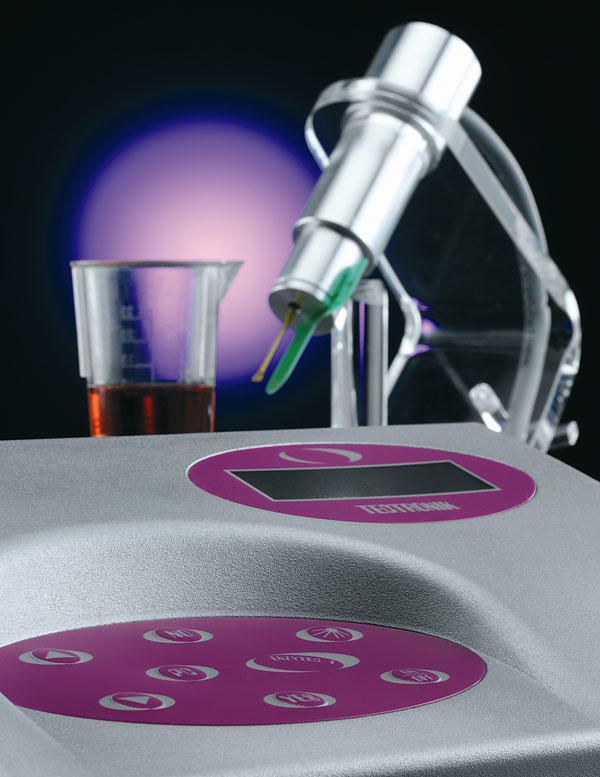

Since construction features lead to significant differences in performance, power consumption and price, the choice of a suitable sensor system is a core challenge. The cost for a sensor system varies from 500 to 7000 Euro, for example. Online sensor systems were tested too, however juice manufacturers clearly prefer the offline system because installation is easier. “Three efficient offline systems are currently being examined in long-run test series at the facilities of those manufacturers who are participating in the project. Depending on requirements and investment cost, all three systems offer certain advantages”, sums up Dr. Hauke Hilz from ttz Bremerhaven. The research service provider is co-ordinator of the QUALI-JUICE project.

Deterioration in the quality of the fruit as a result of storage, climatic conditions or construction defects in production is mostly the cause for subsequent bacterial contamination. With the help of a biosensor system, contamination can be detected within minutes. By comparison: Conventional analysis methods are much more complex and need at least 12 hours to deliver a result. By then, the juice can already be spoilt.

If he is aware of contamination at an early stage, the manufacturer can pasteurise the juice and use it as usual. Since this measure consumes energy and thus raises production costs, it should only be introduced when there is an acute risk of spoilage. In this way, quality assurance is guaranteed and can be offered at a fair price to the customer, since efficient production with minimum waste means a process for the manufacturer where costs are optimised.

A two-level programme is foreseen which will disseminate this knowledge to industry: Firstly, European associations are trained in order to pass on the know-how to their members in the next step. The considerable demand experienced at workshops already held in Poland, Austria, Slovenia, Romania and Spain are evidence of associations’ major interest in learning more about the user-friendly QUALI-JUICE technology. By the end of the project in October, various systems will be ready for market and becoming well known in the fruit juice industry.

Pictures for editorial use (photo: ttz/pr/tectronic)

Download with right mouse button: “Save as…”

ttz Bremerhaven regards itself as an innovative provider of research services and operates in the field of application-oriented research and development. Under the umbrella of ttz Bremerhaven, an international team of experts is working in the areas of food, environment and health.