At the 3rd meeting of the OZONECIP consortium in La Rioja/Spain the prototype for an ozone-based cleaning and disinfection system for food and beverage processing plants was presented. The disinfectant properties of ozone make safe and fast cleaning and disinfection processes possible, avoiding the use of traditional disinfection agents. Assays targeting different ozone based “Cleaning In Place” (CIP) processes in wineries have already started. Subsequent trials will target the diary and the brewery industry.

Bremerhaven, February 2008. Currently cleaning and disinfection operation in the food and beverage industry are mainly carried out with chlorine based chemicals. A European consortium comprising ttz-Bremerhaven, further two research partners and three food and beverage processing industries, will demonstrate within the frame of the EU funded OZONECIP project, the environmental and industrial advantages of using ozone as alternative sanitising agent for cleaning operations in the food industry.

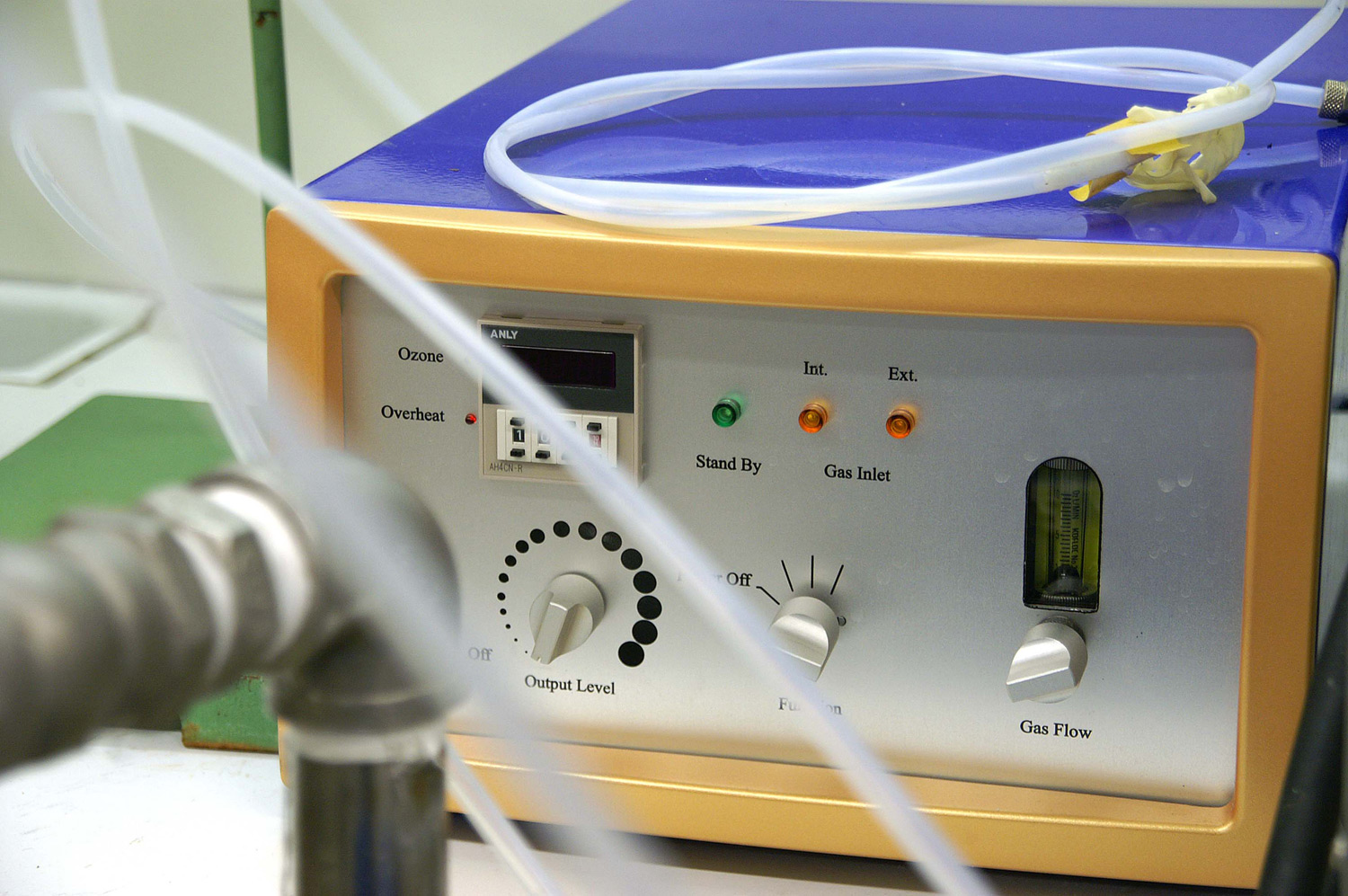

In order to achieve these objectives a prototype was be designed, built and prepared for assaying CIP processes simulating industrial CIP processes currently carried out in breweries, wineries and dairies and assay equivalent processes based on ozone. The experimental results will be the basis for to the definition of environmental indicators and representative values to update “European Best Available Technologies Reference Documents” (BREFs). Besides, models of technical and economical viability will be generically defined to facilitate its practical large scale implementation in the food and beverage industry.

Disinfection with ozone offers several advantages compared to the traditional agents currently applied in food processing plants. Ozone decays back to oxygen after the inactivation of the different microorganisms, so that no chemical by-products remain in the applied water, which enables its re-use. Moreover, no additional water is required, in order to rinse out the applied chemical compounds. The high oxidation potential of ozone reduces considerably the time required for the different disinfection processes. On the other hand, as ozone is applied under low-temperatures, there is no necessity of heating the washing water. This leads to significant economical and environmental advantages. The results of the research activities of OZONECIP will be presented at the “3rd Bremerhaven Ozone Workshop” open to general public, which will take place the 3rd November 2008 in Bremerhaven, Germany.

Additional information about the project Ozonecip can be found in the project description.

Press pictures for editorial use (foto: ttz/pr)

Download with right mouse button: “Save as…”

ttz Bremerhaven regards itself as an innovative provider of research services and operates in the field of application-oriented research and development. Under the umbrella of ttz Bremerhaven, an international team of experts is working in the areas of food, environment, health and consulting services.