In the “Ultrasonic Cutting“ research project, a high-performance cutting machine for baked goods from rye is being developed.

Bakers mostly use rye and wheat cereals when making bread, rolls or baguettes. Baked goods from rye are however difficult to handle. To cut them, they are cooled down from their original core temperature (95-98°C) to 30-35°C, accepting in so doing the subsequently increased risk of microbiological contamination. To preserve the freshness and quality of the product, ttz Bremerhaven is working on the development of an industrial cutting machine within the framework of its “Ultrasonic Cutting” project which makes it possible to cut baked goods containing rye both when hot as well as cold.

Bremerhaven, October 2011. Wheat and rye cereals are the main raw ingredients used in baking. Immediately after the baking process, products made with these ingredients are germ-free. For the benefit of the cutting process however, they are cooled down to about 30°C. Whilst this indeed prevents the crust from being destroyed when the baked goods are cut, the surface of the baked product is particularly susceptible to contamination from microorganisms in the room or ambient air as a result of the relatively long cooling time of about 2 hours. In its “Ultrasonic Cutting” project, ttz Bremerhaven, together with a plant construction firm (Döinghaus cutting and more GmbH & Co. KG), is developing a technology based on ultrasound which makes it possible to cut bread and rolls both in a semi-frozen state as well as in a hot state of about 60°C, in order to keep microbiological contamination as low as possible.

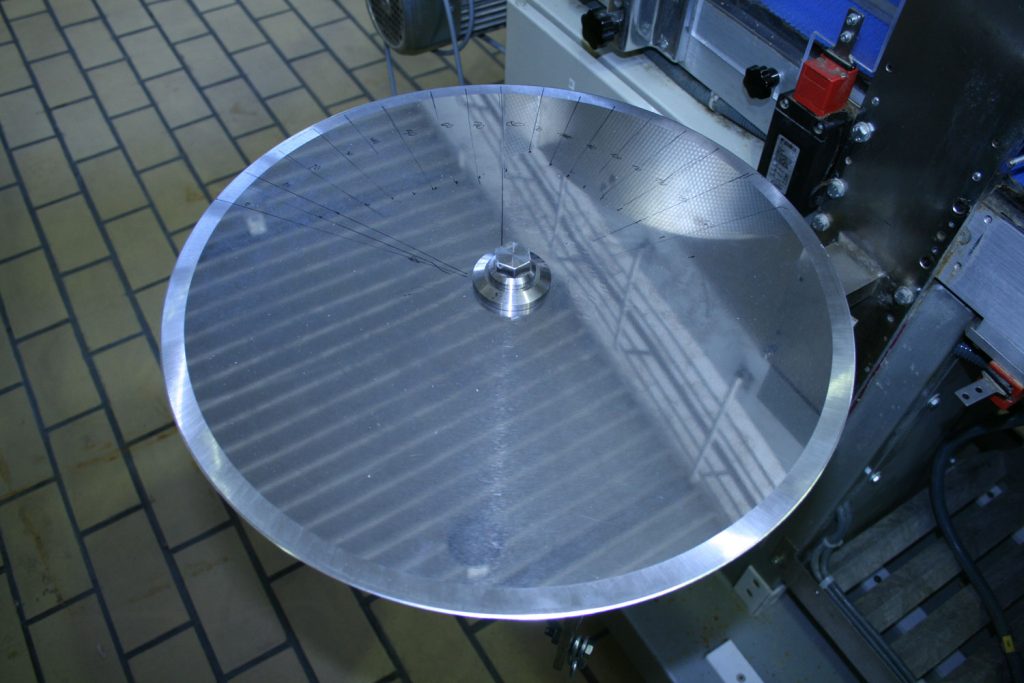

In the framework of the project, the research provider compared two cutting knives and systems: a conventional serrated knife and the new development, an ultrasonic knife with a diameter of 400 mm which can rotate at up to 50 rpm. In addition, knives whetted on just one side were compared with knives whetted on both sides.

Apart from cutting temperature, amongst the variables examined which influence product quality and appearance of the baked goods were also belt speed and rotation of the ultrasonic and serrated knives, baking mould, crust thickness, different percentages of rye flour content or the influence of various levels of acidification in the sourdough. Microbiological tests on the contamination of the baked goods’ surface after the baking process were also implemented.

The trials showed that it is possible with ultrasonic cutting technology to cut products with a core temperature of about 60°C efficiently and with a good quality result. Apart from lowering the risk of microbiological contamination, this innovative cutting technology offers further advantages: Products which are cut with the ultrasonic knife show a significantly better cross section. Whilst products cut with conventional technology have a coarse surface and a rough pore structure, the pores are not destroyed by the ultrasonic knife. In addition, cutting waste compared to conventional cutting technologies is significantly reduced.

Further information on this subject:

Project description: Ultraschallschneiden – Roggen

Project description: Minicrystal

Press release: “Ultrafruits – dried by sound”

Press pictures for editorial use (foto: ttz/pr)

Picture 5:

Products cut at a core temperature of about 60°C with the innovative ultrasonic knife (UK)

Picture 6:

Products cut at a core temperature of about 60°C with the conventional serrated knife (SK)

Picture 7:

Diagram showing the amount of crust depending on knife type. The total mean value for each “knife type” is consolidated in each case from n = 6.

Download with right mouse button: “Save as…”

ttz Bremerhaven is a provider of research services and performs application-based research and development. Under the umbrella of ttz Bremerhaven, an international team of experts is working in the areas of food, environment and health.